-

Facilities

Facilities

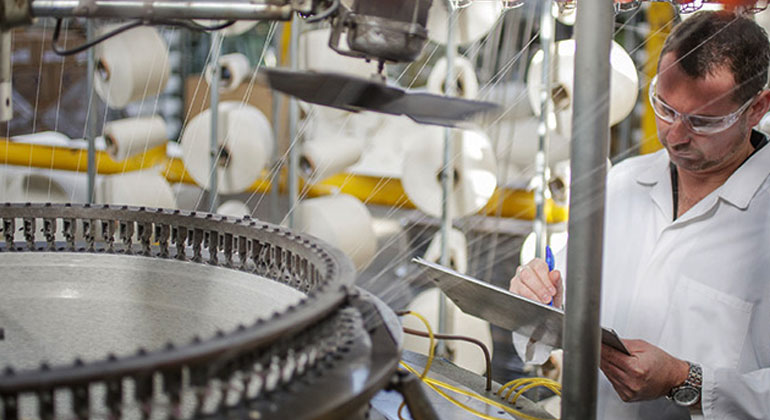

We have a well equipped production unit which is backed by hi-tech machines and state-of-the-art technology. Our infrastructure is backed by excellent manufacturing and processing facility.

Our knitting division is equipped with imported knitting machines. Mayer & Cie machines with Lycra attachments are used for circular knitting and Matsuya machines from Japan are used for Collar.

Knitting, to produce export quality products. Our knit fabrics include:

100% cotton - Single Jersey, Interlock, Rib, Fleece, Pique, Ottoman, Waffle, Popcorn, Yarn Dyed Auto Stripes, Feeder Stripes, Jacquard, etc.Blended fabrics – Viscose, Modal, Polyester, Bamboo, Lycra, etc

Ultra modern soft flow machines are used for dyeing. Electronic color measurement and dyeing ensures even coloring. Squeezers (balloon padding) are used instead of the conventional hydro drier so the fabric is not strained while removing the moisture. The fabric is then processed through relax drier, making sure that the fabric is soft handled and made even softer by the end of this process.

Various types of washing are done to remove hairiness and make the fabrics feel soft, neat and spotless. Washes like Enzyme wash, Silicon wash, Vintage wash, Stone wash and several other types are used. To dry the washed fabrics, we use tubular drying and natural drying facilities.

Value Additions Printing various types of prints like chest prints (done using 8/12 head chest printing machines), rotary prints (done using Stormac 12 color matching), discharge/reactive prints and fancy prints like flock, embossing etc. - are used on garments. Water based printing, Pigment printing and Non- PVC printing are also.

Garments are finely cut with modern machinery for appropriate precision. Each fabric is accurately measured to ensure perfect fit. The cut fabrics are then sewed skillfully to create suitable garments.

Our proficiency lies in making a wide range of printing patterns possible. Towards this, we have table & machine printing facility that enable a diverse variety of prints.

Embroidery20-Head, 9-color, computerised embroidery machines are used by this specialised division. Intricate embroidery designs are created and edited by the computerised designing facility attached to this division.

To create contemporary style garments, our garmenting division is equipped with latest machinery and other ancillary equipments. This division is scientifically laid out with ample lighting, space and the necessary amenities for the convenience of the workforce. This division yields a production of 1,50,000 pieces per month.

Machines available in this division:

Checking: The manufactured garments are checked by our skilled workers. They make sure the quality of the garments is satisfactory and meets the international standards.

Ironing: The verified garments are steam- ironed to make them wrinkle-free and attractive.

Packing: The packaging unit takes care of the packing process. Here garments are neatly packed with utmost care. Once the packaging is done, the garments are sorted out for shipping.